MTS – The missing piece of your bulk handling puzzle

Tonnes per litre of fuel – the new metric for bulk in port operations

As we approach the 20’s of the new millennium, what has changed in the metric of loading and unloading vessels?

Well, productivity, the speed to charge or discharge a vessel remains as important today as it ever has. The method? There are more equipment options available now especially as hydraulic cranes encroach deeper into the territory that were once dominated by MHC’s. Ground conditions seem to plateau – quays built in the last century are certainly not as strong and for obvious reasons, are the last on the investment money tree. Environment? That is a big step-change where cost of fuel and the exhaust emissions represent a huge and at times, emotive, topic but is this conjecture or is there a real change here?

Modern technology has long recorded fuel consumption. This is typically recorded on a litres per hour basis, but this makes no contingency for the operation. If the machine is unnecessarily idling, that brings litres per hour down and how can that be good for the environment? Fuel consumption needs to be measured against productivity of what the handling machine is actually doing or achieving in terms of discharge rate. Enter the new metric of tonnes per litre that encapsulates productivity, economy and environmental impact in one measure.

But what constitutes a strong and a weak tonnes per litre? We know 40mpg is a good fuel consumption and that 30 degrees is a warm ambient temperature. If we have this measure, how do we know it is good or bad? Let us look at an example of two identical machines: –

Machine 1 discharges 800 tonnes in an hour and in this same hour burnt 50 litres per hour = 16 tonnes per litre

Machine 2 discharges 550 tonnes per litre but burns 24 litres per hour = 23 tonnes per litre.

However, there will likely be reasons why the discharge rate is lower on machine 2 – it might be machine waiting, and therein idling or, more likely down to operational bottle-necks that slow handling machines down so the tonnes/litre measure is not just a metric on the machine, it is reflective of the discharge process as a whole. Optimise the operation and the tonnes per litre will soar – it increases load and unloading and is great for the environment.

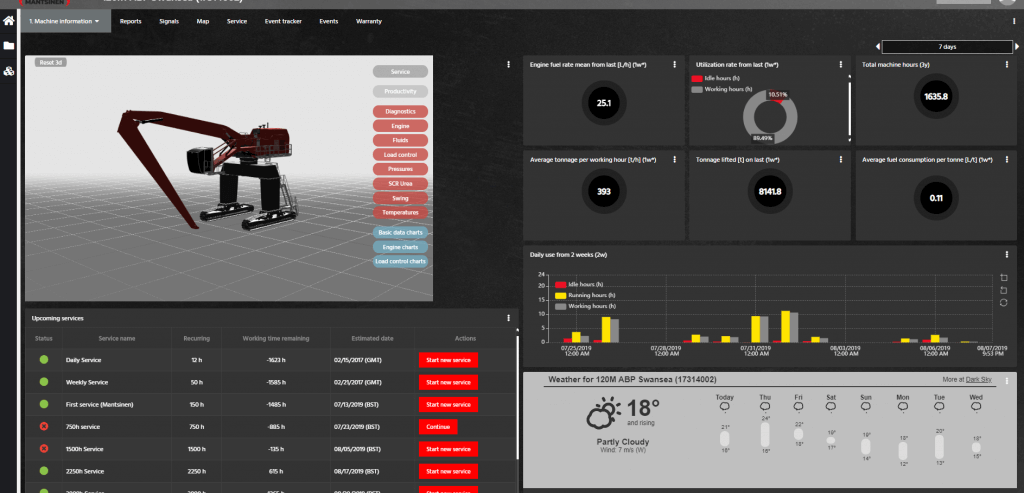

The Mantsinen range of hydraulic cranes provide this data as part of their MTS suite. Mantsinen have, for an over a decade now, been at the forefront of fuel-saving technology, and with MTS now provide an online platform that shows all manner of data which will include the tonnes per litre of fuel.

Tonnes per litre of fuel moved – how do you compare?

To keep up to date with Cooper Handling’s latest News please follow, tweet, link or like @CooperSHGroup